Ford Escape: Exterior Lighting / Diagnosis and Testing - Daytime Running Lamps (DRL)

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

Diagnostic Trouble Code Chart

| Module | DTC | Description | Action |

|---|---|---|---|

| BCM | B124A:11 | Right Daytime Running Light: Circuit Short To Ground | GO to Pinpoint Test A |

| BCM | B124A:15 | Right Daytime Running Light: Circuit Short To Battery or Open | GO to Pinpoint Test A |

| BCM | B124B:11 | Left Daytime Running Light: Circuit Short To Ground | GO to Pinpoint Test A |

| BCM | B124B:15 | Left Daytime Running Light: Circuit Short To Battery or Open | GO to Pinpoint Test A |

Global Customer Symptom Code (GCSC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| Symptom | Action |

|---|---|

| Lighting/Glass/Vision > Exterior Lighting > Daytime Running > Inoperative | GO to Pinpoint Test A |

| Lighting/Glass/Vision > Exterior Lighting > Daytime Running > Stays On | GO to Pinpoint Test A |

Symptom Charts

Symptom Chart: DRL

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

Symptom Chart

NOTE: Before beginning diagnostics, refer to Description and Operation in this section for proper DRL operation.

| Condition | Actions |

|---|---|

| A module does not respond to the diagnostic scan tool |

REFER to: Communications Network (418-00 Module Communications Network, Diagnosis and Testing). |

| The DRL are inoperative or always on | GO to Pinpoint Test A |

| One or both LED DRL /front park lamps do not dim with the parking lamps ON or do not brighten when the parking lamps are OFF - Mid and high series headlamps |

REFER to: Parking, Rear and License Plate Lamps (417-01 Exterior Lighting, Diagnosis and Testing). |

Pinpoint Tests

.jpg) PINPOINT TEST A: THE DRL (DAYTIME RUNNING LAMPS)

ARE INOPERATIVE OR ALWAYS ON

PINPOINT TEST A: THE DRL (DAYTIME RUNNING LAMPS)

ARE INOPERATIVE OR ALWAYS ON|

Refer to Wiring Diagrams Cell 85 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Exterior Lighting - Overview (417-01 Exterior Lighting, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

NOTE: Before beginning this test, refer to Description and Operation in this section for proper DRL operation. |

||||||||||||||||||||||||||||

| A1 CHECK THE OPERATION OF THE PARKING LAMPS | ||||||||||||||||||||||||||||

Do the lamps operate correctly?

|

||||||||||||||||||||||||||||

| A2 CHECK THE BCM (BODY CONTROL MODULE) DRL (DAYTIME RUNNING LAMPS) CIRCUIT FOR A SHORT TO VOLTAGE | ||||||||||||||||||||||||||||

Do the DRL continue to illuminate?

|

||||||||||||||||||||||||||||

| A3 CHECK THAT THE DRL (DAYTIME RUNNING LAMPS) ARE ENABLED | ||||||||||||||||||||||||||||

Are the DRL enabled?

|

||||||||||||||||||||||||||||

| A4 CHECK THE DRL (DAYTIME RUNNING LAMPS) CIRCUIT FOR VOLTAGE | ||||||||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

||||||||||||||||||||||||||||

| A5 REPEAT THE ON-DEMAND SELF-TEST AND CHECK THE DRL (DAYTIME RUNNING LAMPS) CIRCUIT FOR VOLTAGE | ||||||||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

||||||||||||||||||||||||||||

| A6 CHECK THE LED (LIGHT EMITTING DIODE) CONTROL MODULE | ||||||||||||||||||||||||||||

Is the concern still present or does any Diagnostic Trouble Codes (DTCs) return?

|

||||||||||||||||||||||||||||

| A7 CHECK THE DRL (DAYTIME RUNNING LAMPS) CIRCUIT FOR A SHORT TO GROUND | ||||||||||||||||||||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||||||||||||||||||||

| A8 CHECK THE DRL (DAYTIME RUNNING LAMPS) CIRCUIT FOR AN OPEN | ||||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||||||||||||

| A9 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION | ||||||||||||||||||||||||||||

Is the concern still present?

|

Diagnosis and Testing - Autolamps

Diagnosis and Testing - Autolamps

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation)...

Diagnosis and Testing - Fog Lamps

Diagnosis and Testing - Fog Lamps

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation)...

Other information:

Ford Escape 2020-2025 Service Manual: Removal and Installation - Power Transfer Unit Rear Seal

Special Tool(s) / General Equipment 205-199 (T83T-3132-A1) Installer, Spindle/Axle ShaftT83-4000-ATKIT-1983-FTKIT-1983-FLMTKIT-1983-FX 308-777Remover and Installer, PTU Input Shaft Seal 308-969Installer, Pinion Seal Slide Hammer Dent Puller Plastic Mallet Two Leg Puller Removal Remove the PTU...

Ford Escape 2020-2025 Service Manual: Diagnosis and Testing - Headlamps

Diagnostic Trouble Code (DTC) Chart Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation). Diagnostic Trouble Code Chart Module DTC Description Action BCM B14E0..

Categories

- Manuals Home

- 4th Generation Ford Escape Owners Manual

- 4th Generation Ford Escape Service Manual

- Locating the Pre-Collision Assist Sensors

- Symbols Glossary

- Accessing the Trip Computer. Resetting the Trip Computer

- New on site

- Most important about car

Master Access Code

What Is the Master Access Code

The master access code is a factory-set five-digit entry code. You can operate the keypad with the master access code at any time. The master access code is on the owner’s wallet card in the glove box and is available from an authorized dealer.

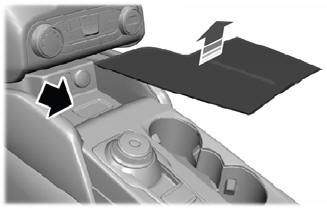

Displaying the Master Access Code

To display the factory-set code in the information display:

.jpg) PINPOINT TEST A: THE DRL (DAYTIME RUNNING LAMPS)

ARE INOPERATIVE OR ALWAYS ON

PINPOINT TEST A: THE DRL (DAYTIME RUNNING LAMPS)

ARE INOPERATIVE OR ALWAYS ON.jpg)

.jpg)