Ford Escape: Engine / Removal and Installation - Oil Pump

Special Tool(s) /

General Equipment

.jpg) |

303-290B-20

Adapter, Car-Bar

TKIT-2014D-ROW3

TKIT-2014D-FL_ROW |

|

303-F070

Support Bar, Engine

TKIT-1999A-F/LT

TKIT-1999A-FM/FLM |

|

303-F072

Support Bar, Engine |

| Oil Drain Equipment |

| Trolley Jack |

| Round-Ended Steel Rule |

| Wooden Block |

Materials

| Name |

Specification |

Motorcraft® High Performance Engine RTV Silicone

TA-357 |

WSE-M4G323-A6

|

Motorcraft® Metal Surface Prep Wipes

ZC-31-B |

-

|

Removal

-

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation).

-

Remove the cowl panel grille.

Refer to: Cowl Panel Grille (501-02 Front End Body Panels, Removal and Installation).

-

Remove the bolts, pin-type retainer and the RH cowl cover.

-

Remove the bolts, pin-type retainer and the LH cowl cover.

-

Remove the coolant pump.

Refer to: Coolant Pump (303-03C Engine Cooling, Removal and Installation).

-

Disconnect the A/C compressor electrical connectors and pin-type retainers.

-

Remove the A/C compressor nut, bolts and position aside.

-

Disconnect the wire harness pin-type retainers, remove the fasteners and bracket.

-

Remove the engine front cover.

Refer to: Engine Front Cover (303-01C Engine, Removal and Installation).

-

Using the feet from 303-F070 and the car bar adapters

303-290B-20 assemble them on the 303-F072 engine support bar and support

the engine.

Install Special Service Tool: 303-F072

Support Bar, Engine.

Install Suggested Tool: 303-290B-20

Adapter, Car-Bar. Tool shown or a commercially available equivalent can be used.

, 303-F070

Support Bar, Engine. Tool shown or a commercially available equivalent can be used.

-

Remove the General Equipment: Trolley Jack

Remove the General Equipment: Wooden Block

-

-

Remove the bolt and drain the engine oil.

Use the General Equipment: Oil Drain Equipment

-

Install the oil drain bolt.

Torque:

21 lb.ft (28 Nm)

-

Remove and discard the oil filter.

-

Remove the bolt.

-

Remove the bolts.

-

Remove the bolts and the oil pan.

-

Make sure that the mating surface is clean and free of foreign material.

Refer to: RTV Sealing Surface Cleaning and Preparation (303-00 Engine System - General Information, General Procedures).

-

Make sure that the mating surface is clean and free of foreign material.

Refer to: RTV Sealing Surface Cleaning and Preparation (303-00 Engine System - General Information, General Procedures).

-

-

Remove the bolts and the oil pickup tube.

-

Remove and discard the oil pickup tube gasket.

-

-

Position out the spring.

-

Remove the bolts and the oil pump chain tensioner.

-

-

Remove the chain from the oil pump drive gear.

-

Remove the bolt and the oil pump drive gear.

-

Remove the bolts and the oil pump.

-

Remove and discard the oil pump gasket.

Installation

-

Prime the oil pump. Add 2 tablespoons of clean engine oil to the oil pump and rotate the oil pump by hand.

-

Install the new oil pump gasket.

-

NOTE:

Clean the oil pump and cylinder block mating surfaces with Motorcraft® Metal Surface Prep.

Install the oil pump and the bolts. Tighten in sequence shown in 2 stages.

Material: Motorcraft® Metal Surface Prep Wipes

/ ZC-31-B

Torque:

Stage 1:

89 lb.in (10 Nm)

Stage 2:

177 lb.in (20 Nm)

-

-

Install the oil pump drive gear and the bolt.

Torque:

18 lb.ft (25 Nm)

-

Install the chain onto the oil pump drive gear.

-

-

Install the oil pump chain tensioner and the bolts.

Torque:

89 lb.in (10 Nm)

-

Push the tensioner spring down and position the spring under the shoulder bolt.

-

Lubricate new gasket with clean engine oil and install.

-

Install the oil pickup tube and the bolts.

Torque:

89 lb.in (10 Nm)

-

NOTE:

If the oil pan is not secured within 10 minutes of

sealant application, the sealant must be removed and the sealing area

cleaned with metal surface prep. Allow to dry until there is no sign of

wetness, or 10 minutes, whichever is longer. Failure to follow this

procedure can cause future oil leakage.

Apply a 3 mm (0.19 in) bead of silicone sealant.

Material: Motorcraft® High Performance Engine RTV Silicone

/ TA-357

(WSE-M4G323-A6)

-

NOTE:

Only tighten the bolts finger tight at this stage.

Install the oil pan and the bolts.

-

Using a straight edge, align the front surface of the oil pan flush with the front surface of the engine block.

Use the General Equipment: Round-Ended Steel Rule

-

Tighten the oil pan bolts in sequence shown.

Torque:

177 lb.in (20 Nm)

-

Install the bolts.

Torque:

35 lb.ft (48 Nm)

-

Install the bolt.

Torque:

35 lb.ft (48 Nm)

-

Install a new oil filter.

Torque:

133 lb.in (15 Nm)

-

NOTE:

Failure to position the wood block and floor jack as illustrated can result in damage to the oil pan.

Using a trolley jack and wooden block, support the engine.

Install the General Equipment: Trolley Jack

Install the General Equipment: Wooden Block

-

Remove the engine support bar.

Remove Special Service Tool: 303-F072

Support Bar, Engine.

, 303-290B-20

Adapter, Car-Bar.

Remove Suggested Tool: 303-F070

Support Bar, Engine.

-

Install the engine front cover.

Refer to: Engine Front Cover (303-01C Engine, Removal and Installation).

-

Install the bracket and fasteners and connect the electrical harness pin-type retainers.

Torque:

18 lb.ft (25 Nm)

-

Position the A/C compressor, install the nut and bolts.

Torque:

18 lb.ft (25 Nm)

-

Connect the A/C compressor electrical connectors and pin-type retainers.

-

Install the coolant pump.

Refer to: Coolant Pump (303-03C Engine Cooling, Removal and Installation).

-

Install the LH cowl cover, bolts and the pin-type retainer.

-

Install the RH cowl cover, bolts and the pin-type retainer.

-

Install the cowl panel grille.

Refer to: Cowl Panel Grille (501-02 Front End Body Panels, Removal and Installation).

-

Fill the engine with clean engine oil.

Refer to: Specifications (303-03C Engine Cooling, Specifications).

Materials

Name

Specification

Motorcraft® Thread Sealant with PTFETA-24-B

WSK-M2G350-A2

Removal

NOTE:

Removal steps in this procedure may contain installation details...

Removal

NOTE:

During engine repair procedures, cleanliness is extremely

important. Any foreign material, including any material created while

cleaning gasket surfaces, that enters the oil passages, coolant passages

or the oil pan can cause engine failure...

Other information:

Item

Description

1

Driver side register

2

In-vehicle temperature & humidity sensor

3

Driver side register air discharge temperature sensor

4

Sunload sensor

5

Passenger side register air discharge temperature sensor

6

Passenger side register

7

Passenger side footwell air discharge temperature sensor

8

Center registers

9

..

Playing Media Using the USB Port

WARNING: Driving while distracted

can result in loss of vehicle control, crash

and injury. We strongly recommend that

you use extreme caution when using any

device that may take your focus off the

road. Your primary responsibility is the

safe operation of your vehicle. We

recommend against the use of any

hand-held device while driving and

encourage the use..

Categories

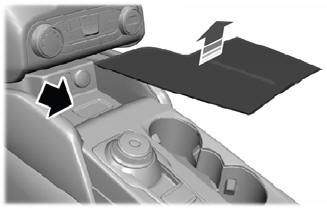

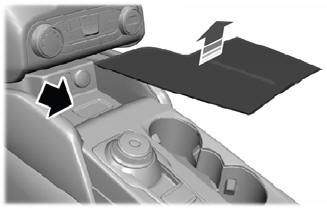

What Is the Master Access Code

The master access code is a factory-set

five-digit entry code. You can operate the

keypad with the master access code at

any time. The master access code is on the

owner’s wallet card in the glove box and

is available from an authorized dealer.

Displaying the Master Access Code

To display the factory-set code in the

information display:

Remove the rubber mat.

Insert the first programmed key in the

backup slot.

Press the push button ignition switch

once and wait a few seconds.

Press the push button ignition switch

again and remove the key.

Within 10 seconds, place a second

programmed intelligent access key in

the backup slot and press the push

button ignition switch.

read more

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Removal and Installation - Oil Pressure Switch

Removal and Installation - Oil Pressure Switch Removal and Installation - Timing Chain

Removal and Installation - Timing Chain