Ford Escape: Engine / Removal and Installation - Crankshaft Pulley

Special Tool(s) /

General Equipment

|

303-1416

Tool, Crank Damper Holding

TKIT-2008ET-FLM |

.jpg) |

303-1699

Tool, Crank Sensor Alignment |

|

303-465

Tool, Camshaft Align Timing

TKIT-1994-LMH/MH2

TKIT-1994-FH/FMH/FLMH |

.jpg) |

303-507

Timing Peg, Crankshaft TDC

TKIT-2001N-FLM

TKIT-2001N-ROW |

| Trolley Jack |

| Wooden Block |

Removal

NOTICE:

Do not loosen or remove the crankshaft pulley bolt without

first installing the special tools as instructed in this procedure. The

crankshaft pulley and the crankshaft timing sprocket are not keyed to

the crankshaft. The crankshaft, the crankshaft sprocket and the pulley

are fitted together by friction. For that reason, the crankshaft

sprocket is also unfastened if the pulley bolt is loosened. Before any

repair requiring loosening or removal of the crankshaft pulley bolt, the

crankshaft and camshafts must be locked in place by the special service

tools, otherwise severe engine damage can occur.

NOTICE:

During engine repair procedures, cleanliness is extremely

important. All parts must be thoroughly cleaned and any foreign

material, including any material created while cleaning gasket surfaces,

that enters the oil passages, coolant passages or the oil pan, can

cause engine failure.

-

Remove the RHF fender splash shield.

Refer to: Fender Splash Shield (501-02 Front End Body Panels, Removal and Installation).

-

Remove the valve cover.

Refer to: Valve Cover (303-01C Engine, Removal and Installation).

-

Remove the bolts and the CKP sensor.

-

Release the tabs and remove the crankshaft pulley cover.

-

NOTE:

Failure to position the No. 1 piston at TDC can result in damage to the

engine. Turn the engine in the normal direction of rotation only.

Using the crankshaft pulley bolt, turn the crankshaft clockwise to position the No. 1 piston at TDC .

-

The hole in the crankshaft pulley should be in the 6 o'clock position.

-

Remove the engine plug bolt.

-

NOTE:

The Crankshaft TDC Timing Peg will contact the crankshaft and prevent

it from turning past TDC . However, the crankshaft can still be rotated

in the counterclockwise direction. The crankshaft must remain at the TDC

position during disassembly.

-

Install Special Service Tool: 303-507

Timing Peg, Crankshaft TDC.

-

Rotate the crankshaft slowly clockwise until the crankshaft balance

weight is up against the Crankshaft TDC Timing Peg. The engine is now at

TDC .

-

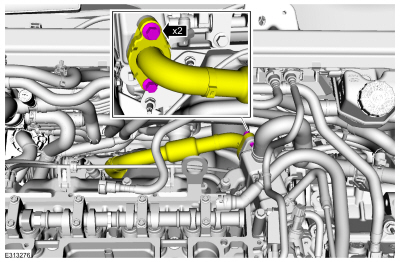

Remove the bolts and position the EGR cooler inlet tube aside.

-

Remove and discard the EGR cooler inlet tube gasket.

-

Remove the bolts and position the EGR cooler aside.

-

NOTE:

The Camshaft Alignment Plate is for camshaft

alignment only. Using this tool to prevent engine rotation can result in

engine damage.

NOTE:

The camshaft timing slots are offset. If the

Camshaft Alignment Plate cannot be installed, rotate the crankshaft one

complete revolution clockwise to correctly position the camshafts.

Install Special Service Tool: 303-465

Tool, Camshaft Align Timing.

-

Position the jack and wooden block under the front of the oil pan to support the engine.

Use the General Equipment: Trolley Jack

Use the General Equipment: Wooden Block

-

Remove and discard the engine mount nuts.

-

Lower the engine 88.9 mm ( 3.5 inches ).

-

Install Suggested Tool: 303-1416

Tool, Crank Damper Holding. Tool shown or a commercially available equivalent can be used.

Use Special Service Tool: 303-507

Timing Peg, Crankshaft TDC.

-

NOTE:

The crankshaft must remain in the TDC

position during removal of the pulley bolt or damage to the engine can

occur. Therefore, the crankshaft pulley must be held in place with the

Crankshaft Damper Holding Tool, and the bolt should be removed using an

air impact wrench (1/2-in drive minimum).

NOTE:

If equipped, the crankshaft sprocket diamond washer may come off with the crankshaft pulley.

NOTE:

Use an air impact wrench to remove the crankshaft pulley bolt.

Use the Crankshaft Damper Holding Tool and a suitable

1/2-in drive hand tool to hold the crankshaft pulley. Use an air impact

wrench to remove the crankshaft pulley bolt.

-

Remove and discard the crankshaft pulley bolt and washer.

-

Remove the crankshaft pulley.

Use Special Service Tool: 303-1416

Tool, Crank Damper Holding.

Installation

-

NOTE:

Do not install the crankshaft pulley bolt at this time.

NOTE:

Component(s) must be lubricated with clean engine oil.

Lubricate the crankshaft pulley oil sealing surface with clean engine oil and install the crankshaft pulley.

Refer to: Specifications (303-01C Engine, Specifications).

-

NOTE:

Only hand-tighten the 6 mm x 18 mm bolt or damage to the front cover can occur.

NOTE:

This step will correctly align the crankshaft pulley to the crankshaft.

Install an M6 bolt.

-

NOTE:

The crankshaft must remain in the TDC

position during installation of the pulley bolt or damage to the

engine can occur. Therefore, the crankshaft pulley must be held in place

with the Crankshaft Damper Holding Tool and the bolt should be

installed using hand tools only.

NOTE:

Install a new crankshaft pulley bolt.

-

Install a new crankshaft pulley bolt. Use the

Crankshaft Damper Holding tool and a suitable 1/2-in drive hand tool to

hold the crankshaft pulley.

-

Tighten the crankshaft pulley bolt in 2 stages.

Use Special Service Tool: 303-1416

Tool, Crank Damper Holding.

Torque:

Stage 1:

74 lb.ft (100 Nm)

Stage 2:

90 °

-

Remove the M6 bolt.

-

Remove Special Service Tool: 303-507

Timing Peg, Crankshaft TDC.

-

Remove Special Service Tool: 303-465

Tool, Camshaft Align Timing.

-

NOTE:

Only turn the engine in the normal direction of rotation.

Turn the crankshaft clockwise one and three-fourth turns.

-

NOTE:

Only turn the engine in the normal direction of rotation.

Install Special Service Tool: 303-507

Timing Peg, Crankshaft TDC.

-

NOTE:

Only hand-tighten the bolt or damage to the front cover can occur.

Install an M6 bolt, check the position of the crankshaft pulley.

-

If it is not possible to install the bolt, the

engine valve timing must be corrected by repeating this procedure.

-

NOTE:

The Camshaft Alignment Plate is for camshaft

alignment only. Using this tool to prevent engine rotation can result in

engine damage.

NOTE:

If it is not possible to install the Camshaft Alignment Plate, the engine valve timing must be corrected.

Install Special Service Tool: 303-465

Tool, Camshaft Align Timing.

-

Remove Special Service Tool: 303-465

Tool, Camshaft Align Timing.

-

Remove the M6 bolt.

-

NOTE:

Only tighten the bolts finger tight at this stage.

Install the CKP sensor and the bolts.

-

If the special service tool mark does not align with the TDC marked

tooth on the crankshaft pulley, loosen the CKP sensor bolts and adjust

the sensor until the tool is installed then tighten.

Use Suggested Tool: 303-1699

Tool, Crank Sensor Alignment. Tool shown or a commercially available equivalent can be used.

Torque:

62 lb.in (7 Nm)

-

Remove Special Service Tool: 303-1699

Tool, Crank Sensor Alignment.

-

Remove Special Service Tool: 303-507

Timing Peg, Crankshaft TDC.

-

Install the engine plug bolt.

Torque:

177 lb.in (20 Nm)

-

Inspect the crankshaft pulley cover tabs for damage replace if necessary.

-

Install the crankshaft pulley cover.

-

Raise the engine.

-

Install the new engine mount nuts.

Torque:

81 lb.ft (110 Nm)

-

Remove the jack and wooden block from under the engine.

Use the General Equipment: Trolley Jack

Use the General Equipment: Wooden Block

-

Inspect the EGR cooler O-ring seal replace if necessary.

-

NOTE:

Component(s) must be lubricated with clean engine oil.

Lubricate the new EGR cooler O-ring with a small amount of engine oil.

-

Position back the EGR cooler.

Torque:

89 lb.in (10 Nm)

-

Install the EGR assembly bolt and hand tighten the bolt at this stage.

-

Install the EGR assembly mounting bolt.

Torque:

89 lb.in (10 Nm)

-

Install the EGR assembly bolts and hand tighten the bolts at this stage.

-

Tighten in the sequence shown.

Torque:

1:

89 lb.in (10 Nm)

2:

89 lb.in (10 Nm)

3:

18 lb.ft (25 Nm)

-

This step only necessary if the water outlet housing was removed or loosened.

Tighten in the sequence shown.

Torque:

Stage 1:

89 lb.in (10 Nm)

Stage 2:

45°

-

Install the new EGR cooler inlet tube gasket.

-

Position back the EGR cooler inlet tube and install the bolts hand tight.

Torque:

22 lb.ft (30 Nm)

-

Tighten in the sequence shown.

Torque:

1:

89 lb.in (10 Nm)

2:

18 lb.ft (24 Nm)

1:

18 lb.ft (24 Nm)

-

Install the valve cover.

Refer to: Valve Cover (303-01C Engine, Removal and Installation).

-

Install the RHF fender splash shield.

Refer to: Fender Splash Shield (501-02 Front End Body Panels, Removal and Installation).

-

After completing repairs, perform the Misfire Monitor

Neutral Profile Correction procedure using a diagnostic scan tool.

Special Tool(s) /

General Equipment

303-096

(T74P-6150-A)

Installer, Camshaft Front Oil SealTKIT-2009TC-F

303-409

(T92C-6700-CH)

Remover, Crankshaft SealTKIT-1992-FH/FMH/FLMHTKIT-1993-LMH/MH

303-507Timing Peg, Crankshaft TDCTKIT-2001N-FLMTKIT-2001N-ROW

Removal

Remove the crankshaft pulley...

Special Tool(s) /

General Equipment

303-328

(T88P-6701-B1)

Replacer, Rear SealTKIT-1988-FLMTKIT-1988-FTKIT-1988-LM

Plastic Scraper

Materials

Name

Specification

Motorcraft® High Performance Engine RTV SiliconeTA-357

WSE-M4G323-A6

Motorcraft® Silicone Gasket RemoverZC-30-A, AZC-30-C

-

Motorcraft® Metal Surface Prep WipesZC-31-B

-

..

Other information:

Removal

NOTE:

Removal steps in this procedure may contain installation details.

NOTE:

Driver seat shown, passenger seat similar.

Remove the front seat.

Refer to: Front Seat (501-10A Front Seats, Removal and Installation).

Remove the front seatbelt buckle.

Detach the wiring harness retainers.

Disconnect the electrical connector.

Remov..

System Operation

System Diagram

NOTE:

The system diagrams include all component options. Some components may not be equipped on the vehicle.

Audio System

*.sttxt {

visibility: hidden;

}

*.stcallout {

visibility: visible;

}

E345256

1

APIM

2

GWM

3

BCM

..

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Removal and Installation - Crankshaft Front Seal

Removal and Installation - Crankshaft Front Seal Removal and Installation - Crankshaft Rear Seal

Removal and Installation - Crankshaft Rear Seal