Ford Escape: Wheels and Tires / General Procedures - Wheel to Tire Runout Minimization

Check

NOTICE: Non-Hunter brand balancers will not include the Ford-approved procedure for match-mounting in their software.

NOTICE: Other balancing procedures that exist on non-Hunter brand equipment are not Ford approved and should not be used.

NOTE: Road Force® values in illustrations are shown in pounds.

NOTE: Match mounting is a technique used to reduce radial runout or road force on wheel and tire assemblies. Excessive runout is a source of ride quality complaints and match mounting can be used to minimize the runout. Match mounting can be accomplished by changing the position of the tire on the wheel.

NOTE: Diagnosis of tire/wheel vibration should not be performed on tires with less than 200 mi (322 km).

NOTE: Possible short-term tire flat-spotting should be eliminated by driving the vehicle 20 or more miles just prior to taking Road Force® measurements.

-

To ensure a tire/wheel vibration is the cause of the customer concern.

Refer to: Noise, Vibration and Harshness (NVH) (100-04) .

-

To eliminate possible short-term tire flat-spotting

drive the vehicle 20 or more miles just prior to taking Road Force®

measurements.

-

Before a warranty claim can be made on tire(s) with

out-of-spec Road Force® or runout measurements, the Wheel to Tire Runout

Minimization procedure (sometimes referred to as “match-mounting”,

“re-indexing”, or “Road Force® balancing”) found below must be

performed. This procedure is designed to optimize a tire’s mounting

position on a wheel in order to reduce the total Road Force® or runout

of the assembly. The procedure can be performed using either Road Force®

measurements (the preferred method). Road Force® measurements are taken

using a Road Force® balancer machine. The manner in which the Wheel to

Tire Runout Minimization procedure is carried out will sometimes vary

depending on the model of equipment used. Use the information below to

help identify the equipment type used at your dealership, then follow

the instructions outlined for that equipment. If your equipment

software does not include the Ford-approved procedure, it may be

available through hardware/software upgrades. Contact your local Hunter

representative for more details.

-

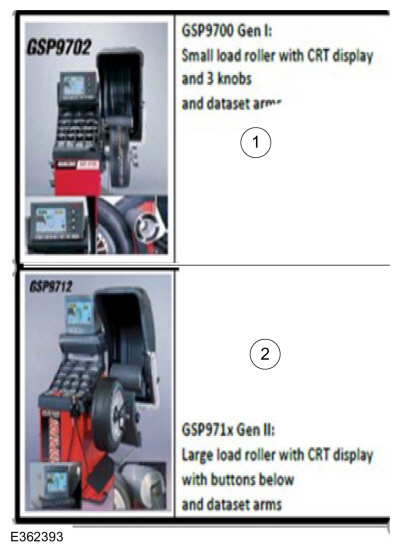

Determine the equipment type used at dealership or

tire/wheel balancing. Refer Hunter Equipment Model Identification for

identifying equipment type.

|

-

GEN I and GEN II

-

Gen I and Gen II balancer models do not include software that follows the Ford Workshop Manual methodology.

-

The match-mounting procedures in the software of

these models should not be used. Instead, only the Wheel to Tire Runout

Minimization Procedure found above, should be used.

-

Use these machines only to gather the necessary Road

Force® measurements. Do not follow the prompts that appear for

match-mounting.

-

Gen I and Gen II balancer models do not include software that follows the Ford Workshop Manual methodology.

|

-

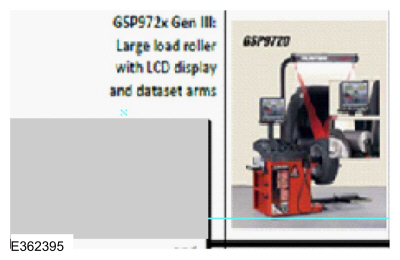

GEN III

-

Gen III model balancer may include a procedure for

“Match Without Rim Runout” on the balancer display. If this procedure

is not included, then the Wheel to Tire Runout Minimization Procedure

above should be followed.

-

Another balancing procedure likely exists on Gen

III equipment. Do not use that procedure, only the Hunter “Match

Without Rim Runout” and Ford WSM Wheel to Tire Runout Minimization

Procedure are approved for use on Ford tire/wheel assemblies.

-

The “Match Without Rim Runout” procedure should

become the machine default setting after the first usage. If it does

not become the default than you will need to select it each time.

-

Gen III model balancer may include a procedure for

“Match Without Rim Runout” on the balancer display. If this procedure

is not included, then the Wheel to Tire Runout Minimization Procedure

above should be followed.

|

-

GEN IV and GEN V

-

Gen IV and GEN V balancer models include a procedure

for “180 Matching” on the balancer display. This is the only Hunter

procedure that matches the Wheel to Tire Runout Minimization Procedure.

-

A second balancing procedure (it may be the default)

likely exists on your equipment. Do not use that procedure. If you

cannot default your machine to the 180 Matching Procedure, then it will

need to be selected each time.

-

The 180 Matching Procedure can be launched by

selecting the following buttons: Road Force® - Procedures - 180

Matching.

-

Gen IV and GEN V balancer models include a procedure

for “180 Matching” on the balancer display. This is the only Hunter

procedure that matches the Wheel to Tire Runout Minimization Procedure.

|

-

The 180 Matching Procedure can be launched by selecting the following buttons:

-

Road Force®

-

Procedures

-

180 Matching

-

Road Force®

|

-

NOTE: Position the wheel and tire assembly on a tire machine and put a reference mark on the tire sidewall at the valve stem position.

-

Valve stem

-

Reference mark

-

Valve stem

|

-

NOTICE: For vehicles equipped with a TPMS , the sensor may be damaged by incorrect tire mounting or dismounting. Dismount the tire from the wheel as instructed in the procedure. Failure to follow these instructions may result in TPMS component damage.

NOTE: Always make sure that the final high spot and measurement values are permanently marked on the inward sidewall of the tire for reference during future wheel and tire service.

Using a suitable tire machine, separate the tire beads from the wheel.

-

Lubricate the tire beads using a suitable fast drying,

corrosion inhibiting tire bead lubricant. Position the tire 180 degrees

(half-way around) on the rim so the valve stem reference mark is now

opposite the valve stem.

-

Re-inflate the wheel and tire assembly to the specified

air pressure and measure the assembly again using a suitable dial

indicator or Hunter Road Force® 9700 Series Wheel Balancer. Mark the

second high spot on the tire.

-

If the runout or Road Force is reduced to within

specifications, the concern has been resolved. Balance the assembly and

install on the vehicle using the Wheel-to-Hub Optimization procedure.

-

If the second runout or Road Force® measurement is still

not within specification and both high spots are close to each other

(within 101.6 mm [4 in]), the root cause is probably the tire (the high

spot followed the tire).

-

-

First high spot on the tire

-

Second high spot on the tire

-

First high spot on the tire

|

-

To be SURE that the tire is causing the high runout, it

is necessary to have 2 runout or Road Force® measurements that are not

within specification and the high spots must be in approximately the

same location on the tire's sidewall. If the tire is the cause, install a

new tire, balance the assembly and install on the vehicle using the

Wheel-to-Hub Optimization procedure. If the second high spot is not

within 101.6 mm (4 in) of the first high spot, proceed to the next step.

-

If the second high spot is still above specification and

is within 101.6 mm (4 in) of being opposite the first high spot on the

wheel, the root cause is probably the wheel (the high spot followed the

wheel). Dismount the tire from the wheel, mount the wheel on a balancer

and check the wheel runout. If the wheel runout exceeds 1.14 mm (0.0449

in), install a new wheel, balance the assembly and install on the

vehicle using the Wheel-to-Hub Optimization procedure.

Refer to: Wheel to Hub Runout Minimization (204-04A Wheels and Tires, General Procedures).

-

-

First high spot on the tire

-

Second high spot on the tire

-

First high spot on the tire

|

-

NOTE: If the second high spot did not follow the wheel or the tire and the runout is still not within specification, improvements may be made by rotating the tire 90 degrees (one-fourth turn).

Draw an arrow on the tire sidewall from the second high spot towards the first high spot (in the shortest direction).

-

-

First high spot on the tire

-

Second high spot on the tire

-

First high spot on the tire

|

-

Separate the tire beads from the wheel and rotate the

tire 90 degrees (one-fourth turn) in the direction of the arrow.

General Procedures - Wheel to Hub Runout Minimization

General Procedures - Wheel to Hub Runout Minimization

Check

NOTE:

Wheel-to-hub optimization is important. Clearance between

the wheel and hub can be used to offset or neutralize the Road Force® or

run-out of the wheel and tire assembly...

Removal and Installation - Wheel and Tire

Removal and Installation - Wheel and Tire

Materials

Name

Specification

Motorcraft® High Temperature Nickel Anti-Seize LubricantXL-2

-

Removal

With the vehicle in NEUTRAL, position it on a hoist...

Other information:

Ford Escape 2020-2026 Owners Manual: How Do the Front Airbags Work

The driver and front passenger airbags deploy during significant frontal and near frontal crashes. The driver and passenger front airbag system consists of: Driver and passenger airbag modules. Front passenger sensing system. Crash sensors and monitoring system with readiness indicator...

Ford Escape 2020-2026 Service Manual: General Procedures - Headlamp Adjustment

Adjustment NOTE: If the flash video link does not load or is incompatible with your browser, a .wmv version of the video can be accessed at: http://www.fordservicecontent.com/Ford_Content/videos/FusionHeadlampAdj2.wmv Click on the link above to view video...

Categories

- Manuals Home

- 4th Generation Ford Escape Owners Manual

- 4th Generation Ford Escape Service Manual

- General Procedures - Brake Service Mode Activation and Deactivation

- Switching the Rear Window Wiper On and Off. Reverse Wipe

- Rear View Camera

- New on site

- Most important about car

Symbols Glossary

These are some of the symbols you may see on your vehicle.

Air conditioning system

Air conditioning system