Ford Escape: Evaporative Emissions / General Procedures - Evaporative Emission System Leak Test

Check

NOTE: Steps 1 to 7 are diagnosing potential leaks in the evaporative emissions system between the canister and the evaporative emissions system purge valve.

-

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting (100-02 Jacking and Lifting - 2.5L Duratec – Hybrid (121kW/164PS) (BG)) .

-

NOTICE: Do not apply smoke to the EVAP leak detection control module. Internal module damage may result.

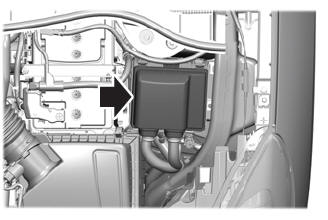

NOTE: Typical evaporative emissions canister shown.

Disconnect the evaporative emissions system purge line and connect the VACUTEC Smoke Machine Fuel Evaporative Emission Tester to the evaporative purge line quick connect fitting where shown. Refer to the manufacturer's instructions.

Refer to: Quick Release Coupling (310-00 Fuel System - General Information - 2.5L Duratec – Hybrid (121kW/164PS) (BG)) .

|

-

Using the VACUTEC Smoke Machine Fuel Evaporative Emission Tester, pressurize the EVAP system.

-

Monitor the indicator flag on the VACUTEC Smoke Machine

Fuel Evaporative Emission Tester. If the measurement is below the

indicator flag, the system has passed the leak test and the test

procedure is complete. If the measurement is above the indicator flag,

the system has failed the leak test. If the leak test has failed,

proceed to next step.

-

Introduce smoke from the VACUTEC Smoke Machine Fuel Evaporative

Emission Tester into the EVAP system. Refer to the manufacturer's

instructions.

-

Use the halogen spotlight provided with the VACUTEC

Smoke Machine Fuel Evaporative Emission Tester to look for smoke coming

from the EVAP system. This would indicate a leak point.

-

Repair any leaks as necessary and reinstall components.

NOTE: Steps 8 to 13 are diagnosing potential leaks in the evaporative emissions system between the canister and the Tank Pressure Control valve (TPC) and the Refueling Valve (RV) valve.

-

NOTICE: Do not apply smoke to the EVAP leak detection control module. Internal module damage may result.

NOTE: Typical evaporative emissions canister shown.

NOTE: This test is completed with the Tank Pressure Control Valve (TPC) and the Refueling Valve (RV) in the normally closed position and tests these two components for leaks.

Disconnect the evaporative emissions system load line and connect the VACUTEC Smoke Machine Fuel Evaporative Emission Tester to the emissions system load line quick connect fitting where shown. Refer to the manufacturer's instructions.

Refer to: Quick Release Coupling (310-00 Fuel System - General Information - 2.5L Duratec – Hybrid (121kW/164PS) (BG)) .

|

-

Using the VACUTEC Smoke Machine Fuel Evaporative Emission Tester, pressurize the EVAP system.

-

Monitor the indicator flag on the VACUTEC Smoke Machine

Fuel Evaporative Emission Tester. If the measurement is below the

indicator flag, the system has passed the leak test and the test

procedure is complete. If the measurement is above the indicator flag,

the system has failed the leak test. If the leak test has failed,

proceed to next step.

-

Introduce smoke from the VACUTEC Smoke Machine Fuel Evaporative

Emission Tester into the EVAP system. Refer to the manufacturer's

instructions.

-

Use the halogen spotlight provided with the VACUTEC

Smoke Machine Fuel Evaporative Emission Tester to look for smoke coming

from the EVAP system. This would indicate a leak point.

-

Repair any leaks as necessary and reinstall components.

NOTE: Steps 14 to 20 are diagnosing potential leaks in the evaporative emissions system between the canister and the fuel tank and associated components.

-

NOTICE: Do not apply smoke to the EVAP leak detection control module. Internal module damage may result.

NOTE: This test is completed with the evaporative system switching valve (EVAP_SW_VLV) in the open position and tests the fuel tank and associated vapor and fuel lines for leaks.

With the evaporative emissions system load line previously disconnected from step 8, connect the VACUTEC Smoke Machine Fuel Evaporative Emission Tester to the emissions system load line quick connect fitting where shown. Refer to the manufacturer's instructions.

Refer to: Quick Release Coupling (310-00 Fuel System - General Information - 2.5L Duratec – Hybrid (121kW/164PS) (BG)) .

-

Using FDRS , command the evaporative system switching valve (EVAP_SW_VLV) into the open position.

|

-

Using the VACUTEC Smoke Machine Fuel Evaporative Emission Tester, pressurize the EVAP system.

-

Monitor the indicator flag on the VACUTEC Smoke Machine

Fuel Evaporative Emission Tester. If the measurement is below the

indicator flag, the system has passed the leak test and the test

procedure is complete. If the measurement is above the indicator flag,

the system has failed the leak test. If the leak test has failed,

proceed to next step.

-

Introduce smoke from the VACUTEC Smoke Machine Fuel Evaporative

Emission Tester into the EVAP system. Refer to the manufacturer's

instructions.

-

Use the halogen spotlight provided with the VACUTEC

Smoke Machine Fuel Evaporative Emission Tester to look for smoke coming

from the EVAP system. This would indicate a leak point.

-

Repair any leaks as necessary and reinstall components.

NOTE: Steps 21 to 28 are diagnosing potential leaks in the evaporative emissions canister body.

-

Item Port 1 Load Port 2 Purge Port 3 Fresh Air Port 4 Dust Box 5 ELCM

|

-

Remove the evaporative emission canister.

Refer to: Evaporative Emission Canister - Plug-In Hybrid Electric Vehicle (PHEV) (303-13C Evaporative Emissions, Removal and Installation).

-

Use suitable plugs or caps to seal the load and purge ports on the evaporative emission canister.

-

Purge the VACUTEC Smoke Machine Fuel Evaporative

Emission Tester to atmosphere to clear it of smoke if it has been

operated in smoke mode during previous tests.

-

NOTICE: Do not apply smoke to the EVAP leak detection control module. Internal module damage may result.

Connect the VACUTEC Smoke Machine Fuel Evaporative Emission Tester to the fresh air port.

-

Spray the evaporative emission canister with soapy water.

-

Apply pressure (not smoke) and check the evaporative

emission canister for leaks. Leaks can be identified by the presence of

bubbles in the soapy water.

-

Repair any leaks or replace the components as necessary.

-

NOTE: In addition to the VACUTEC leak check, an IDS or FDRS HEV routine is available to run the on-board leak test. This leak test should indicate whether a leak is present or not but does not necessarily show where the leak is located. The FDRS takes approximately 12 to 17 minutes to run depending on fuel level.

The test is located on FDRS via Self Test > PCM > Perform KOEO Evap Leak Test. Repeat the leak test until the system passes.

Diagnosis and Testing - Evaporative Emissions

Diagnosis and Testing - Evaporative Emissions

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation)...

Removal and Installation - Evaporative Emission Canister - Plug-In Hybrid Electric Vehicle (PHEV)

Removal and Installation - Evaporative Emission Canister - Plug-In Hybrid Electric Vehicle (PHEV)

Removal

WARNING:

Do not smoke, carry lighted tobacco or have an open flame of

any type when working on or near any fuel-related component...

Other information:

Ford Escape 2020-2026 Service Manual: Diagnosis and Testing - Seatbelt Systems

Symptom Chart(s) Preliminary Inspection Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation). Before diagnosing or repairing the seatbelt system, inspect the following items: Seatbelt webbing integrity (torn, frayed, cut or stretched) Seatb..

Ford Escape 2020-2026 Owners Manual: Load Carrying Precautions

Keep your loaded vehicle weight within its design rating capability, with or without a trailer. Properly loading your vehicle provides maximum return of vehicle design performance. Before you load your vehicle, become familiar with the following terms for determining your vehicle’s weight rating, with or without a trailer, from the vehicle’s Tire and Loading Information label or Saf..

Categories

- Manuals Home

- 4th Generation Ford Escape Owners Manual

- 4th Generation Ford Escape Service Manual

- Drive Modes

- Opening and Closing the Hood

- Switching the Lane Keeping System On and Off. Switching the Lane Keeping System Mode. Alert Mode

- New on site

- Most important about car

Under Hood Fuse Box

Locating the Under Hood Fuse Box

Accessing the Under Hood Fuse Box