Ford Escape 2020-2025 Service Manual / Powertrain / Engine / Engine System - General Information / General Procedures - Cylinder Block Distortion

Ford Escape: Engine System - General Information / General Procedures - Cylinder Block Distortion

Special Tool(s) / General Equipment

| Feeler Gauge |

Check

NOTE: Refer to the appropriate Section 303-01 for the specification.

-

NOTE: Use a Straightedge that is calibrated by the manufacturer to be flat within 0.005 mm (0.0002 in) per running foot of length, such as Snap-On® GA438A or equivalent. For example, if the Straightedge is 61 cm (24 in) long, the machined edge must be flat within 0.010 mm (0.0004 in) from end to end.

Use a Straightedge and a Feeler Gauge Set to inspect the cylinder block for flatness.

Use the General Equipment: Feeler Gauge

|

General Procedures - Cylinder Block Core Plug Replacement

General Procedures - Cylinder Block Core Plug Replacement

Special Tool(s) /

General Equipment

100-001

(T50T-100-A)

Slide Hammer

Materials

Name

Specification

Motorcraft® Threadlock and SealerTA-25-B

-

Repair

All core plugs

NOTE:

Cylinder block core plug shown, cylinder head core plug similar...

General Procedures - Cylinder Bore Taper

General Procedures - Cylinder Bore Taper

Check

NOTE:

Refer to the appropriate Section 303-01 for the specification.

Measure the cylinder bore at the top, middle and bottom

of piston ring travel in 2 directions as indicated...

Other information:

Ford Escape 2020-2025 Owners Manual: Automatic Return to Park (P)

What Is Automatic Return to Park (P) Your vehicle shifts into park (P) if you attempt to exit your vehicle without the transmission in park (P). How Does Automatic Return to Park (P) Work Your vehicle shifts into park (P) when your vehicle is stationary and any of the following occur: You switch the vehicle off...

Ford Escape 2020-2025 Service Manual: Description and Operation - Instrument Panel Cluster (IPC) - Overview

Overview The IPC uses the following methods and functionality to alert the driver of vehicle conditions: gauges informational indicators warning indicators warning messages warning chimes The base IPC uses a single centered 4-inch screen to display driver information with analog gauges...

Categories

- Manuals Home

- 4th Generation Ford Escape Owners Manual

- 4th Generation Ford Escape Service Manual

- Locating the Pre-Collision Assist Sensors

- All-Wheel Drive

- Accessing the Trip Computer. Resetting the Trip Computer

- New on site

- Most important about car

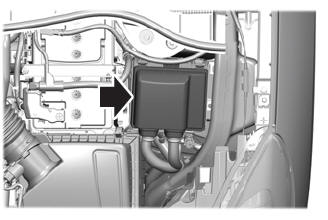

Under Hood Fuse Box

Locating the Under Hood Fuse Box

Accessing the Under Hood Fuse Box

Copyright © 2025 www.fordescape4.com