Ford Escape: Fuel Tank and Lines / Diagnosis and Testing - Fuel Tank and Lines

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| Module | DTC | Description | Action |

|---|---|---|---|

| PCM | P008A:00 | Low Pressure Fuel System Pressure - Too Low: No Sub Type Information | GO to Pinpoint Test HC |

| PCM | P008B:00 | Low Pressure Fuel System Pressure - Too High: No Sub Type Information | GO to Pinpoint Test HC |

| PCM | P00BA:00 | Low Fuel Pressure -Forced Limited Power: No Sub Type Information | GO to Pinpoint Test HC |

| PCM | P00BB:00 | Fuel Injector Insufficient Flow -Forced Limited Power: No Sub Type Information | GO to Pinpoint Test HC |

| PCM | P0148:00 | Fuel Delivery Error: No Sub Type Information | GO to Pinpoint Test HC |

| PCM | P0230:00 | Fuel Pump Primary Circuit: No Sub Type Information | GO to Pinpoint Test KC |

| PCM | P0231:00 | Fuel Pump Secondary Circuit Low: No Sub Type Information | GO to Pinpoint Test KC |

| PCM | P0232:00 | Fuel Pump Secondary Circuit High: No Sub Type Information | GO to Pinpoint Test KC |

| PCM | P025A:00 | Fuel Pump Module 'A' Control Circuit/Open: No Sub Type Information | GO to Pinpoint Test KC |

| PCM | P025B:00 | Fuel Pump Module 'A' Control Circuit Range/Performance: No Sub Type Information | GO to Pinpoint Test KC |

| PCM | P025C:00 | Fuel Pump Module 'A' Control Circuit Low: No Sub Type Information | GO to Pinpoint Test KC |

| PCM | P025D:00 | Fuel Pump Module 'A' Control Circuit High: No Sub Type Information | GO to Pinpoint Test KC |

| PCM | P027B:00 | Fuel Pump Module 'B' Control Circuit Range/Performance: No Sub Type Information | GO to Pinpoint Test KC |

| PCM | P0627:00 | Fuel Pump 'A' Control Circuit/Open: No Sub Type Information | GO to Pinpoint Test KC |

| PCM | P064A:00 | Fuel Pump Control Module 'A': No Sub Type Information | GO to Pinpoint Test KC |

| PCM | P166A:00 | Restraints Deployment Communication Circuit: No Sub Type Information | GO to Pinpoint Test KC |

| PCM | P2632:00 | Fuel Pump 'B' Control Circuit/Open: No Sub Type Information | GO to Pinpoint Test KC |

| PCM | P26EA:00 | Fuel Pump Control Module 'B': No Sub Type Information | GO to Pinpoint Test KC |

| PCM | U0109:00 | Lost Communication With Fuel Pump Control Module 'A': No Sub Type Information | GO to Pinpoint Test KC |

| PCM | U016C:00 | Lost Communication With Fuel Pump Control Module 'B': No Sub Type Information | GO to Pinpoint Test KC |

| PCM | U210B:00 | Lost Communication Between Fuel Pump Control Module 'A' and Restraints Control Module: No Sub Type Information | GO to Pinpoint Test KC |

Global Customer Symptom Code (GCSC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| Symptom | Action |

|---|---|

| Start/Run/Move > Starting > Hard Start/Long Crank > Always | GO to Pinpoint Test HC |

| Start/Run/Move > Starting > Hard Start/Long Crank > Hot | GO to Pinpoint Test HC |

| Driving Performance > Lack/Loss of Power > Cruise/ Steady Speed > Always | GO to Pinpoint Test HC |

| Driving Performance > Hesitates/Stumble > Cruise/ Steady Speed > Hot | GO to Pinpoint Test HC |

Pinpoint Tests

PINPOINT TEST HC: FUEL DELIVERY SYSTEM

PINPOINT TEST HC: FUEL DELIVERY SYSTEM.jpg)

Introduction Introduction

NOTE: Replacement fuel injectors may not be the same color as the original injectors in the vehicle. Verify the replacement injector is correct for the application by part number. NOTE: With the engine running, the FRP PID value may be higher than a fuel pressure reading taken with a mechanical gauge. Normal Operation and Fault Conditions Refer to the DTC Fault Trigger Conditions. DTC Fault Trigger Conditions

Possible Sources

|

PINPOINT TEST KC: FUEL PUMP CONTROL MODULE

PINPOINT TEST KC: FUEL PUMP CONTROL MODULE.jpg)

Introduction Introduction

Normal Operation and Fault Conditions Refer to the DTC Fault Trigger Conditions. DTC Fault Trigger Conditions

Possible Sources

|

Description and Operation - Fuel Tank and Lines - System Operation and Component Description

Description and Operation - Fuel Tank and Lines - System Operation and Component Description

System Operation

Fuel Systems

The fuel system supplies the fuel injectors with clean fuel at a

controlled pressure. The PCM controls the fuel pump and monitors the

fuel pump circuit...

Removal and Installation - Fuel Level Sender

Removal and Installation - Fuel Level Sender

Removal

NOTE:

Removal steps in this procedure may contain installation details.

Remove the fuel pump sender unit.

Disconnect the electrical connector...

Other information:

Ford Escape 2020-2025 Service Manual: Description and Operation - Electronic Engine Controls - System Operation and Component Description

System Operation Comprehensive Component Monitor (CCM) The comprehensive component monitor (CCM) checks for concerns in any powertrain electronic component or circuit that provides input or output signals to the PCM that can affect emissions and is not monitored by another OBD monitor...

Ford Escape 2020-2025 Service Manual: General Procedures - Compression and Cylinder Leakage Test - 2.5L Duratec – Hybrid (121kW/164PS) (BG)

NOTE: The compression test requires cranking the engine a minimum of 5 compression strokes with the throttle plate in the wide-open position for each cylinder. The engine cranking diagnostic mode must be used to crank the engine and the brake/accelerator pedals must be used to position the throttle plate during the compression test...

Categories

- Manuals Home

- 4th Generation Ford Escape Owners Manual

- 4th Generation Ford Escape Service Manual

- Switching the Rear Window Wiper On and Off. Reverse Wipe

- Rear View Camera

- Fuel Quality

- New on site

- Most important about car

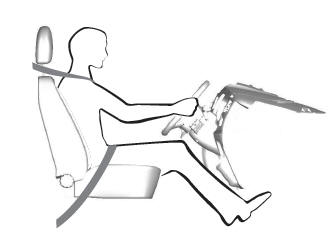

Sitting in the Correct Position

When you use them properly, the seat, head restraint, seatbelt and airbags will provide optimum protection in the event of a crash.

.jpg) PINPOINT TEST HC: FUEL DELIVERY SYSTEM

PINPOINT TEST HC: FUEL DELIVERY SYSTEM

Introduction

Introduction

.jpg) WARNING:

Before working on or disconnecting any of the fuel

tubes or fuel system components, relieve the fuel system pressure to

prevent accidental spraying of fuel. Fuel in the fuel system remains

under high pressure, even when the engine is not running. Failure to

follow this instruction may result in serious personal injury.

WARNING:

Before working on or disconnecting any of the fuel

tubes or fuel system components, relieve the fuel system pressure to

prevent accidental spraying of fuel. Fuel in the fuel system remains

under high pressure, even when the engine is not running. Failure to

follow this instruction may result in serious personal injury.