|

Normal Operation and Fault Conditions

DTC Fault Trigger Conditions

| DTC |

Description |

Fault Trigger Condition |

| PCM P144B:00 |

EVAP System Secondary Purge Vapor Line Restricted/Blocked: No Sub Type Information |

Evaporative Emission System Secondary Purge Vapor Line Restricted/Blocked

|

| PCM P24C0:00 |

EVAP System Leak Detection Pump Switching Valve Stuck On: No Sub Type Information |

Evaporative Emission System Leak Detection Pump Switching Valve Stuck On

|

Possible Sources

|

| A1 CHECK THE FUEL SYSTEM COMPONENTS FOR SIGNS OF DAMAGE |

-

Visually inspect the following components for signs of damage:

-

Fuel tank filler pipe

-

Fuel tank filler pipe vent tube, if equipped

-

EVAP system (Look for kinked or bent vapor lines)

-

Fuel tank inlet check valve (part of the fuel tank)

-

Fuel level vent valve (part of the fuel tank)

-

EVAP canister (may be saturated with liquid)

Are any of the components damaged?

| Yes |

REPAIR or INSTALL a new components to correct the concern.

|

|

| A2 CHECK THE SYSTEM FOR ANY INDICATION TYPE DTC (DIAGNOSTIC TROUBLE CODE)

S |

-

Using a diagnostic scan tool, perform the PCM self-test.

-

Check for any of the following indication DTC s: P25B0, P0461, P0462, P0463.

Are any indication DTCs present?

| Yes |

If DTC 's are present, correct the associated issue. or Workshop manual

|

| No |

If no DTC 's proceed to check for EVAP

DTC s. GO to A3

|

|

| A3 CHECK THE SYSTEM FOR ANY EVAP (EVAPORATIVE EMISSION)

DTCS |

-

Using a diagnostic scan tool, perform the PCM self-test.

-

Check the PCM for any of the EVAP

DTC s: P00FE, P04B4, P04F0, P0496, P24BE, P24BF, P24C1, P144B, P2418, P2450, P2451, P0451, P0452 and P0453.

Are any EVAP system DTC's present?

| Yes |

If DTC 's are present, correct the associated issue.

|

|

| A4 MONITOR THE FTP WHILE FILLING THE FUEL TANK |

-

Monitor the fuel tank pressure (FTP) for typical diagnostic reference values while filling the fuel tank.

Is the FTP less than 1" H2O / 0.25 kPa?

| No |

Is the FTP less than 12" H2O / 3.0 kPa?

Yes :

GO to A6

No :

GO to A7

|

|

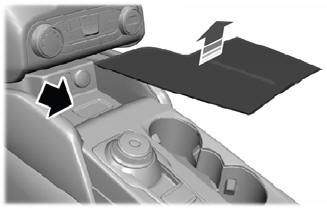

| A5 INSPECT THE FUEL FILLER PIPE & VAPOR RECIRCULATION LINE ASSEMBLY |

-

Disconnect the fuel filler pipe from the fuel tank.

-

Inspect the fuel filler pipe for damage or blockage.

Is the fuel filler pipe assembly blocked or damaged?

| Yes |

Replace the fuel filler pipe assembly.

REFER to: Fuel Tank Filler Pipe (310-01C Fuel Tank and Lines, Removal and Installation).

|

| No |

Replace the fuel tank assembly.

REFER to: Fuel Tank (310-01C Fuel Tank and Lines, Removal and Installation).

|

|

| A6 REFUEL USING A DIFFERENT FUEL FILL NOZZLE |

-

Using a different fuel pump nozzle, monitor the fuel

tank pressure (FTP) for typical diagnostic reference values while

filling the fuel tank.

Is the FTP less than 12" H2O / 3.0 kPa?

| Yes |

System Normal - Unable to identify the root cause at this time.

|

|

| A7 DIAGNOSE THE FRESH AIR HOSE |

-

Disconnect the fresh air line from evaporative leak detection pump (ELDP).

Is the fresh air hose blocked or damaged?

| Yes |

Repair / Replace the fresh air hose.

|

|

| A8 DIAGNOSE THE EVAPORATIVE LEAK DETECTION PUMP (ELDP) |

-

Disconnect the evaporative leak detection pump (ELDP) from the Evap canister.

-

Monitor the fuel tank pressure (FTP) to typical diagnostic reference values while filling the fuel tank.

Is the FTP less than 12" H2O / 3.0 kPa?

| Yes |

Remove / Replace the evaporative leak detection pump (ELDP).

REFER to: Evaporative Emission System Leak Test (303-13C Evaporative Emissions, General Procedures).

|

|

| A9 DIAGNOSE THE EVAP CANISTER |

-

Disconnect the EVAP canister from the fuel vapor load line.

-

Monitor the fuel tank pressure (FTP) to typical diagnostic reference values while filling the fuel tank.

Is the FTP less than 12" H2O / 3.0 kPa?

| Yes |

Remove / Replace the EVAP canister.

REFER to: Evaporative Emission Canister Purge Valve (303-13C Evaporative Emissions, Removal and Installation).

|

| No |

Remove / Replace the fuel vapor line including the

fuel vapor vent valve (FVVV) and Tank Pressure Control Valve (TPC).

|

|

.jpg) PINPOINT TEST A: SLOW TO FILL

PINPOINT TEST A: SLOW TO FILL.jpg) PINPOINT TEST B: DTC P04B0

PINPOINT TEST B: DTC P04B0.jpg) PINPOINT TEST C: P04B4

PINPOINT TEST C: P04B4  Description and Operation - Fuel System - Overview

Description and Operation - Fuel System - Overview General Procedures - Fuel Tank Draining

General Procedures - Fuel Tank Draining

PINPOINT TEST A: SLOW TO FILL

PINPOINT TEST A: SLOW TO FILL.jpg)