Ford Escape: Engine Cooling / Diagnosis and Testing - Engine Cooling

Special Tool(s)

|

Coolant/Battery Refractometer ROB75240 or equivalent |

.jpg)

|

D-Gas Adapter 300-OTC014-R1068 or equivalent |

|

Radiator Tester 014-R1072 or equivalent |

.jpg)

|

UView® Combustion Leak Tester UVU560000-R |

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| Module | DTC | Description | Action |

|---|---|---|---|

| PCM | P0125:00 | Insufficient Coolant Temp For Closed Loop Fuel Control: No Sub Type Information | GO to Pinpoint Test C |

| PCM | P0128:00 | Coolant Thermostat (Coolant Temp Below Thermostat Regulating Temperature): No Sub Type Information | GO to Pinpoint Test C |

| PCM | P01E4:00 | Engine Coolant Temperature Sensor 3 Circuit Range/Performance: No Sub Type Information | GO to Pinpoint Test F |

| PCM | P01E5:00 | Engine Coolant Temperature Sensor 3 Circuit Low: No Sub Type Information | GO to Pinpoint Test F |

| PCM | P01E6:00 | Engine Coolant Temperature Sensor 3 Circuit High: No Sub Type Information | GO to Pinpoint Test F |

| PCM | P0217:00 | Engine Coolant Overtemperature Condition: No Sub Type Information | GO to Pinpoint Test B |

| PCM | P1299:00 | Cylinder Head Overtemperature Protection Active: No Sub Type Information | GO to Pinpoint Test B |

| PCM | P237C:00 | Exhaust Heat Exchanger Exhaust Bypass Valve 'A' Control Circuit/Open: No Sub Type Information | GO to Pinpoint Test D |

| PCM | P237D:00 | Exhaust Heat Exchanger Exhaust Bypass Valve 'A' Control Circuit Low: No Sub Type Information | GO to Pinpoint Test D |

| PCM | P237E:00 | Exhaust Heat Exchanger Exhaust Bypass Valve 'A' Control Circuit High: No Sub Type Information | GO to Pinpoint Test D |

| PCM | P237F:00 | Exhaust Heat Exchanger Exhaust Bypass Valve 'A' Control Performance: No Sub Type Information | GO to Pinpoint Test D |

| PCM | P26CA:00 | Engine Coolant Pump Control Circuit/Open: No Sub Type Information | GO to Pinpoint Test E |

| PCM | P26CB:00 | Engine Coolant Pump Performance/Stuck Off: No Sub Type Information | GO to Pinpoint Test E |

| PCM | P26CE:00 | Engine Coolant Pump Overspeed/Air In System: No Sub Type Information | GO to Pinpoint Test A |

| PCM | P26D0:00 | Engine Coolant Pump Control Module System Voltage Low: No Sub Type Information | GO to Pinpoint Test E |

| PCM | P26D1:00 | Engine Coolant Pump Control Module System Voltage High: No Sub Type Information | GO to Pinpoint Test E |

| PCM | P26D2:00 | Engine Coolant Pump Control Module Over Temperature: No Sub Type Information | GO to Pinpoint Test B |

| PCM | P26D3:00 | Engine Coolant Pump Supply Voltage Circuit: No Sub Type Information | GO to Pinpoint Test E |

| PCM | P2AFD:00 | Engine Coolant Temperature Sensor 4 Circuit Range/Performance: No Sub Type Information | GO to Pinpoint Test G |

| PCM | P2AFE:00 | Engine Coolant Temperature Sensor 4 Circuit Low: No Sub Type Information | GO to Pinpoint Test G |

| PCM | P2AFF:00 | Engine Coolant Temperature Sensor 4 Circuit High: No Sub Type Information | GO to Pinpoint Test G |

| PCM | P2C22:00 | Exhaust Heat Exchanger Exhaust Bypass Valve 'A' Position Sensor Circuit: No Sub Type Information | GO to Pinpoint Test D |

| PCM | P2C23:00 | Exhaust Heat Exchanger Exhaust Bypass Valve 'A' Position Sensor Performance: No Sub Type Information | GO to Pinpoint Test D |

| PCM | U019F:00 | Lost Communication With Engine Coolant Pump Control Module: No Sub Type Information | GO to Pinpoint Test E |

Global Customer Symptom Code (GCSC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| Symptom | Action |

|---|

Symptom Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| Condition | Actions |

| Loss of coolant | GO to Pinpoint Test A |

| The engine overheats. | GO to Pinpoint Test B |

| The engine does not reach normal operating temperature. | GO to Pinpoint Test C |

| The block heater does not operate correctly. (if equipped) |

|

| The electric cooling fan is inoperative in one or more speeds or does not operate correctly. |

REFER to: Cooling Fan Control (303-03C Engine Cooling, Diagnosis and Testing). |

| The electric cooling fan stays on all the time. |

REFER to: Cooling Fan Control (303-03C Engine Cooling, Diagnosis and Testing). |

| Auxiliary coolant pump failure | GO to Pinpoint Test E |

Pinpoint Tests

PINPOINT TEST A: LOSS OF COOLANT

PINPOINT TEST A: LOSS OF COOLANT|

Normal Operation and Fault Conditions The engine cooling system is a closed system providing for coolant expansion and contraction as well as changes in pressure as coolant warms and cools with engine operation. Various gaskets, seals, hoses and clamps contain coolant within the cooling system and keep other fluids and contaminants from entering the cooling system. DTC Fault Trigger Conditions

Possible Sources

|

||||||

| A1 CARRY OUT INSPECTION AND VERIFICATION | ||||||

Are any concerns present?

|

||||||

| A2 CHECK THE ENGINE COOLANT LEVEL AND PRESSURE TEST THE ENGINE COOLING SYSTEM | ||||||

|

NOTE: Allow the engine to cool before checking the engine coolant level.

Does the engine cooling system leak externally?

|

||||||

| A3 CHECK THE ENGINE COOLANT FOR AN INTERNAL LEAK | ||||||

Is engine oil evident in the engine coolant?

|

||||||

| A4 CHECK THE ENGINE OIL FOR COOLANT | ||||||

Is coolant evident in the oil?

|

||||||

| A5 CHECK THE ENGINE COOLANT FOR TRANSMISSION FLUID | ||||||

Is transmission fluid evident in the engine coolant?

|

||||||

| A6 CHECK THE TRANSMISSION FLUID FOR ENGINE COOLANT | ||||||

Is engine coolant evident in the transmission fluid?

|

||||||

| A7 CHECK THE COOLING SYSTEM FOR COMBUSTION GASES | ||||||

|

NOTE: Use UView® Combustion Leak Tester part number UVU560000-R or equivalent.

Are combustion gases present?

|

PINPOINT TEST B: THE ENGINE OVERHEATS

PINPOINT TEST B: THE ENGINE OVERHEATS|

Normal Operation and Fault Conditions The engine cooling system maintains the engine temperature during operation. Correct coolant flow through the engine, radiator and remainder of cooling system passages and components is essential to maintaining a correct engine temperature. DTC Fault Trigger Conditions

Possible Sources

|

||||||||||||

| B1 CARRY OUT INSPECTION AND VERIFICATION | ||||||||||||

Are any concerns present?

|

||||||||||||

| B2 CHECK FOR PCM (POWERTRAIN CONTROL MODULE) DTCS | ||||||||||||

Is DTC P0217 and/or P1299 present?

|

||||||||||||

| B3 CHECK FOR ACTIVE GRILL SHUTTER DTCS | ||||||||||||

Are any active grill shutter DTCs present?

|

||||||||||||

| B4 CHECK FOR AN AIRFLOW OBSTRUCTION AND MISSING AIR DEFLECTORS | ||||||||||||

|

NOTE: Verify no vehicle front end damage is present.

Is an airflow obstruction present or air deflectors missing?

|

||||||||||||

| B5 CHECK THE ENGINE COOLANT LEVEL AND PRESSURE TEST THE COOLING SYSTEM | ||||||||||||

Does the engine cooling system leak externally?

|

||||||||||||

| B6 CHECK THE ENGINE COOLANT FOR AN INTERNAL LEAK | ||||||||||||

Is engine oil evident in the coolant?

|

||||||||||||

| B7 CHECK THE ENGINE OIL FOR COOLANT | ||||||||||||

Is coolant evident in the oil?

|

||||||||||||

| B8 CHECK THE ENGINE COOLANT FOR TRANSMISSION FLUID | ||||||||||||

Is transmission fluid evident in the engine coolant?

|

||||||||||||

| B9 CHECK THE TRANSMISSION FLUID FOR ENGINE COOLANT | ||||||||||||

Is engine coolant evident in the transmission fluid?

|

||||||||||||

| B10 CHECK THE COOLING SYSTEM FOR COMBUSTION GASES | ||||||||||||

|

NOTE: Use UView® Combustion Leak Tester part number UVU560000-R or equivalent.

Are combustion gases present?

|

||||||||||||

| B11 CHECK COOLANT CONDITION | ||||||||||||

Is the coolant condition OK?

|

||||||||||||

| B12 CHECK THE ELECTRIC COOLING FAN OPERATION | ||||||||||||

Did the electric cooling fan operate?

|

||||||||||||

| B13 CHECK THE COOLANT PUMP OPERATION | ||||||||||||

Is the heater outlet hose hot?

|

||||||||||||

| B14 CHECK THE THERMOSTAT OPERATION | ||||||||||||

|

NOTE: This cooling system uses a cold side thermostat. The coolant in the radiator must reach full operating temperature for the thermostat to remain in an open state.

Is the lower radiator hose hot?

|

||||||||||||

| B15 VISUALLY INSPECT THE THERMOSTAT | ||||||||||||

Is the thermostat damaged?

|

PINPOINT TEST C: THE ENGINE DOES NOT REACH NORMAL OPERATING TEMPERATURE

PINPOINT TEST C: THE ENGINE DOES NOT REACH NORMAL OPERATING TEMPERATURE|

Normal Operation and Fault Conditions The engine cooling system maintains engine temperature during operation. Correct coolant flow through the engine, radiator and remainder of cooling system passages and components is essential to maintaining a correct engine temperature. Engine coolant flows primarily from the engine to the radiator circuit and back to the coolant pump. Coolant is sent from the coolant pump through the engine block and cylinder head. A separate circuit from the engine also feeds the heater core with coolant. The coolant pump circulates the coolant. The coolant thermostat is a control valve actuated by coolant temperature. When the thermostat is closed, coolant flow bypasses the radiator circuit and returns to the coolant pump. When the thermostat is opened, coolant flows through the radiator circuit in order to transfer engine generated heat to the outside air. Concerns of engine inability to reach normal operating temperature typically occur when the rate of coolant flow through some coolant circuits (radiator, heater core) is more than expected given the conditions. Heat is not allowed to build in the engine because a heat exchanger is removing too much heat, including the radiator, heater core and oil cooler. In addition, perceived concerns that the engine does not reach normal operating temperature can be related to a low coolant level or trapped air which does not allow for hot coolant to be available at the heater core, an inoperative climate control system, or for concerns perceived or related to an incorrect engine temperature gauge indication. DTC Fault Trigger Conditions

Possible Sources

|

|||||||||

| C1 CARRY OUT INSPECTION AND VERIFICATION | |||||||||

Were any concerns found?

|

|||||||||

| C2 CHECK FOR DTC P0125 OR P0128 | |||||||||

Is DTC P0125 or P0128 present?

|

|||||||||

| C3 CHECK THE COOLANT LEVEL | |||||||||

|

NOTE: Allow the engine to cool before checking the coolant expansion tank.

Is the engine coolant level within specification?

|

PINPOINT TEST D: EXHAUST HEAT EXCHANGER EXHAUST BYPASS VALVE

PINPOINT TEST D: EXHAUST HEAT EXCHANGER EXHAUST BYPASS VALVE |

Refer to Wiring Diagrams Cell 23 for schematic and connector information. Normal Operation and Fault Conditions DTC Fault Trigger Conditions

Possible Sources

|

|||||||||||||||||||||||||

| D1 RETRIEVE AND RECORD ALL DTCS | |||||||||||||||||||||||||

Was DTC P237C, P237D, P237E, P237F, P2C22 or P2C23 set?

|

|||||||||||||||||||||||||

| D2 CHECK THE EXHAUST HEAT EXCHANGER PID | |||||||||||||||||||||||||

Is fault status code 3 or 160 hZ present?

|

|||||||||||||||||||||||||

| D3 CHECK THE EXHAUST HEAT EXCHANGER FOR DAMAGE | |||||||||||||||||||||||||

Was DTC P237C, P237D, P237E, P237F, P2C22 or P2C23 set and is fault status code 3 or 160 hZ present?

|

|||||||||||||||||||||||||

| D4 CHECK THE EXHAUST HEAT EXCHANGER EXHAUST BYPASS VALVE CIRCUITS FOR A SHORT TO VOLTAGE | |||||||||||||||||||||||||

Is there any voltage present?

|

|||||||||||||||||||||||||

| D5 CHECK THE EXHAUST HEAT EXCHANGER EXHAUST BYPASS VALVE CIRCUITS FOR A SHORT TO GROUND | |||||||||||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

|||||||||||||||||||||||||

| D6 CHECK THE EXHAUST HEAT EXCHANGER EXHAUST BYPASS VALVE CIRCUITS FOR AN OPEN | |||||||||||||||||||||||||

Are the resistances less than 3 ohms?

|

|||||||||||||||||||||||||

| D7 CHECK THE EXHAUST HEAT EXCHANGER EXHAUST BYPASS VALVE CIRCUITS FOR A SHORT TOGETHER | |||||||||||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

|||||||||||||||||||||||||

| D8 CHECK FOR CORRECT PCM (POWERTRAIN CONTROL MODULE) OPERATION | |||||||||||||||||||||||||

Is the concern still present?

|

PINPOINT TEST E: THE ELECTRIC COOLANT PUMP IS INOPERATIVE OR DOES NOT OPERATE CORRECTLY

PINPOINT TEST E: THE ELECTRIC COOLANT PUMP IS INOPERATIVE OR DOES NOT OPERATE CORRECTLY|

Refer to Wiring Diagrams Cell 33 for schematic and connector information. Normal Operation and Fault Conditions DTC Fault Trigger Conditions

Possible Sources

|

|||||||||||||||||||||

| E1 CHECK THE ELECTRIC COOLANT PUMP ELECTRICAL CONNECTOR, FUSES, AND CHASSIS GROUND | |||||||||||||||||||||

Were any concerns present?

|

|||||||||||||||||||||

| E2 PERFORM A WIGGLE TEST WHILE USING THE ACTIVE COMMAND FUNCTION ON THE SCAN TOOL | |||||||||||||||||||||

Did the electric coolant pump remain ON and remain OFF when using output state control?

|

|||||||||||||||||||||

| E3 RECORD THE PCM (POWERTRAIN CONTROL MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||||||||||||||

Are Diagnostic Trouble Codes (DTCs) P26CA, P26D0, P26D1, P26D3, P26CB and/or U019F present?

|

|||||||||||||||||||||

| E4 CHECK THE ELECTRIC COOLANT PUMP SUPPLY CIRCUIT VOLTAGE | |||||||||||||||||||||

Is the voltage greater than 11 volts?

|

|||||||||||||||||||||

| E5 CHECK THE ELECTRIC COOLANT PUMP GROUND CIRCUIT FOR AN OPEN | |||||||||||||||||||||

Is the resistance less than 3 ohms?

|

|||||||||||||||||||||

| E6 CHECK THE ELECTRIC COOLANT PUMP CONTROL CIRCUIT VOLTAGE | |||||||||||||||||||||

Is the voltage greater than 11 volts?

|

|||||||||||||||||||||

| E7 CHECK THE LIN (LOCAL INTERCONNECT NETWORK) CIRCUIT FOR AN OPEN | |||||||||||||||||||||

Is the resistance less than 3 ohms?

|

|||||||||||||||||||||

| E8 CHECK THE LIN (LOCAL INTERCONNECT NETWORK) FOR A SHORT TO VOLTAGE | |||||||||||||||||||||

Is any voltage present?

|

|||||||||||||||||||||

| E9 CHECK THE LIN (LOCAL INTERCONNECT NETWORK) FOR A SHORT TO VOLTAGE WITH THE ACTIVE GRILLE SHUTTER ACTUATOR DISCONNECTED | |||||||||||||||||||||

Is any voltage present?

|

|||||||||||||||||||||

| E10 CHECK THE LIN (LOCAL INTERCONNECT NETWORK) CIRCUIT FOR A SHORT TO GROUND | |||||||||||||||||||||

Is the resistance greater than 10,000 ohms?

|

|||||||||||||||||||||

| E11 CHECK THE LIN (LOCAL INTERCONNECT NETWORK) CIRCUIT FOR A SHORT TO GROUND WITH THE ACTIVE GRILLE SHUTTER ACTUATOR DISCONNECTED | |||||||||||||||||||||

Is the resistance greater than 10,000 ohms?

|

|||||||||||||||||||||

| E12 CHECK FOR CORRECT PCM (POWERTRAIN CONTROL MODULE) OPERATION | |||||||||||||||||||||

Is the concern still present?

|

PINPOINT TEST F: ENGINE COOLANT TEMPERATURE SENSOR 3

PINPOINT TEST F: ENGINE COOLANT TEMPERATURE SENSOR 3|

Refer to Wiring Diagrams Cell 23 for schematic and connector information. DTC Fault Trigger Conditions

Possible Sources

NOTICE: Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector. NOTE: Before performing this pinpoint test, ensure the high voltage battery is at least 50 % charged. For charging information, refer to section 414-03. |

||||||||||||||||

| F1 CHECK THE COOLANT HOSE ROUTING | ||||||||||||||||

|

NOTE: Routing of the coolant hoses is critical to proper engine cooling system operation.

Are the coolant hoses routed correctly?

|

||||||||||||||||

| F2 CHECK THE ECT (ENGINE COOLANT TEMPERATURE) SENSOR 3 CIRCUITS FOR A SHORT TO VOLTAGE | ||||||||||||||||

Is there any voltage present?

|

||||||||||||||||

| F3 CHECK THE ECT (ENGINE COOLANT TEMPERATURE) SENSOR 3 CIRCUITS FOR A SHORT TO GROUND | ||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

||||||||||||||||

| F4 CHECK THE ECT (ENGINE COOLANT TEMPERATURE) SENSOR 3 CIRCUITS FOR AN OPEN | ||||||||||||||||

Are the resistances less than 3 ohms?

|

||||||||||||||||

| F5 CHECK THE ECT (ENGINE COOLANT TEMPERATURE) SENSOR 3 CIRCUITS FOR A SHORT TOGETHER | ||||||||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||||||||

| F6 CHECK THE RESISTANCE OF THE ECT (ENGINE COOLANT TEMPERATURE) SENSOR 3 | ||||||||||||||||

Is the resistance between 0.527-1108 KOhms and does the resistance increase and decrease inversely proportional to engine coolant temperature?

|

||||||||||||||||

| F7 CHECK FOR CORRECT PCM (POWERTRAIN CONTROL MODULE) OPERATION | ||||||||||||||||

Is the concern still present?

|

PINPOINT TEST G: ENGINE COOLANT TEMPERATURE SENSOR 4

PINPOINT TEST G: ENGINE COOLANT TEMPERATURE SENSOR 4|

Refer to Wiring Diagrams Cell 23 for schematic and connector information. DTC Fault Trigger Conditions

Possible Sources

NOTICE: Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector. NOTE: Before performing this pinpoint test, ensure the high voltage battery is at least 50 % charged. For charging information, refer to section 414-03. |

||||||||||||||||

| G1 CHECK THE COOLANT HOSE ROUTING | ||||||||||||||||

|

NOTE: Routing of the coolant hoses is critical to proper engine cooling system operation.

Are the coolant hoses routed correctly?

|

||||||||||||||||

| G2 CHECK THE ECT (ENGINE COOLANT TEMPERATURE) SENSOR 4 CIRCUITS FOR A SHORT TO VOLTAGE | ||||||||||||||||

Is there any voltage present?

|

||||||||||||||||

| G3 CHECK THE ECT (ENGINE COOLANT TEMPERATURE) SENSOR 4 CIRCUITS FOR A SHORT TO GROUND | ||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

||||||||||||||||

| G4 CHECK THE ECT (ENGINE COOLANT TEMPERATURE) SENSOR 4 CIRCUITS FOR AN OPEN | ||||||||||||||||

Are the resistances less than 3 ohms?

|

||||||||||||||||

| G5 CHECK THE ECT (ENGINE COOLANT TEMPERATURE) SENSOR 4 CIRCUITS FOR A SHORT TOGETHER | ||||||||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||||||||

| G6 CHECK THE RESISTANCE OF THE ECT (ENGINE COOLANT TEMPERATURE) SENSOR 4 | ||||||||||||||||

Is the resistance between 0.527-1108 KOhms and does the resistance increase and decrease inversely proportional to engine coolant temperature?

|

||||||||||||||||

| G7 CHECK FOR CORRECT PCM (POWERTRAIN CONTROL MODULE) OPERATION | ||||||||||||||||

Is the concern still present?

|

Component Tests

Cooling System Pressure Test

.jpg) WARNING:

Always allow the engine to cool before opening the

cooling system. Do not unscrew the coolant pressure relief cap when the

engine is operating or the cooling system is hot. The cooling system is

under pressure; steam and hot liquid can come out forcefully when the

cap is loosened slightly. Failure to follow these instructions may

result in serious personal injury.

WARNING:

Always allow the engine to cool before opening the

cooling system. Do not unscrew the coolant pressure relief cap when the

engine is operating or the cooling system is hot. The cooling system is

under pressure; steam and hot liquid can come out forcefully when the

cap is loosened slightly. Failure to follow these instructions may

result in serious personal injury.

NOTE: Vehicles have a pressure relief cap on the degas bottle and no radiator cap.

-

Turn the engine OFF.

-

Check the engine coolant level and adjust as necessary.

-

Remove the degas bottle cap. Inspect the degas bottle

cap and degas bottle for any issues that would cause improper sealing,

such as for cross-threading, burrs, damaged o-ring, etc. If any issues

are found, or if coolant was expelled through the cap potentially

leaving contamination in the gasket, INSTALL a new cap and/or degas

bottle.

-

Attach the Pressure Tester and adaptor (Snap-On TA53 or

equivalent), to the degas bottle cap. The cap must hold pressure of 145

kPa +/- 21 kPa (21 PSI +/- 3 PSI). If any issues are found, INSTALL a

new cap.

-

Attach the Pressure Tester and adaptor (Snap-On TA52,

AST ASSFZ-47, Redline RDL95-0750 or equivalent) to the degas bottle.

.jpg)

-

NOTICE: Do not pressurize the cooling system beyond the maximum pressure listed in the Specifications table in this section or cooling system components may be damaged.

NOTE: If the plunger of the pressure tester is pressed too fast, an erroneous pressure reading results.

To pressurize the engine cooling system, slowly press the plunger of the pressure test pump and increase the pressure to between 124 - 138 kPa (18 - 20 PSI). Observe the gauge reading for approximately 2 minutes. Pressure should not drop during this time. If the pressure drops within this time, inspect for leaks and repair as necessary.

-

If no leaks are found and the pressure drops, the leak

may be internal to the engine. Inspect the coolant for engine oil and

the engine oil for coolant.

REFER to: Engine (303-00 Engine System - General Information, Diagnosis and Testing).

-

If the pressure does not drop remove the cooling system Pressure Tester and adaptor from degas bottle.

-

Install the degas bottle cap until it contacts the hard stop.

Thermostat

Install a new thermostat only after at least one of the following tests and checks have been carried out:

- Pinpoint Test B or C

- Thermostat Visual Inspection

Thermostat Visual Inspection

-

Remove the thermostat.

-

Examine the thermostat for signs of damage including:

- Valve not fully seated (light visible through the valve)

- Foreign material lodged in the main valve

- Bent or broken frame or flange

- Bent or broken spring

- Wax leaking from wax reservoir or a bulge in the reservoir

- Any other damage or distortion

-

NOTE: If no damage is found during the inspection, do not attempt to open the thermostat using hot water or other heat sources. This method is not an accurate means to test the function of the thermostat and may damage the thermostat.

If damage is found during the inspection, remove any foreign material or broken pieces and install a new thermostat.

Radiator Leak Test, Removed From Vehicle

NOTICE: Never leak test an aluminum radiator in the same water that copper/brass radiators are tested in. Flux and caustic cleaners may be present in the cleaning tank and they will damage aluminum radiators.

NOTE: Clean the radiator before leak testing to avoid contamination of tank.

-

Leak test the radiator in clean water with air

pressurized to the maximum pressure listed in the Specifications table.

Diagnosis and Testing - Cooling Fan Control

Diagnosis and Testing - Cooling Fan Control

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.REFER to: Diagnostic Methods (100-00 General Information, Description and Operation)...

Diagnosis and Testing - Engine Temperature

Diagnosis and Testing - Engine Temperature

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation)...

Other information:

Ford Escape 2020-2025 Owners Manual: Wipers

Wiper Precautions Do not operate the wipers on a dry windshield. This could scratch the glass or damage the wiper blades. Use the windshield washers before wiping a dry windshield. Fully defrost the windshield before you switch the windshield wipers on...

Ford Escape 2020-2025 Service Manual: Removal and Installation - Front Door Speaker

Removal NOTE: Removal steps in this procedure may contain installation details. NOTE: LH front door speaker is shown, RH side front door speaker is similar. Remove the LH front door interior trim panel. Refer to: Front Door Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation)...

Categories

- Manuals Home

- 4th Generation Ford Escape Owners Manual

- 4th Generation Ford Escape Service Manual

- Drive Modes

- Symbols Glossary

- Adjusting the Headlamps

- New on site

- Most important about car

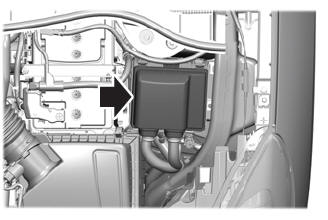

Under Hood Fuse Box

Locating the Under Hood Fuse Box

Accessing the Under Hood Fuse Box

PINPOINT TEST A: LOSS OF COOLANT

PINPOINT TEST A: LOSS OF COOLANT.jpg)

.jpg)

.png) VIN required to access Guided Routine (PCM)

If the condition is still present, INSTALL a new muffler inlet pipe.

VIN required to access Guided Routine (PCM)

If the condition is still present, INSTALL a new muffler inlet pipe.