Ford Escape: Body Repairs - Vehicle Specific Information and Tolerance Checks / General Procedures - Body Panel Sectioning

Special Tool(s) / General Equipment

| Resistance Spotwelding Equipment | |

| Spherical Cutter | |

| Air Body Saw | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Repair

.jpg) WARNING:

Electric vehicles damaged by a crash may have compromised

high voltage safety systems and present a potential high voltage

electrical shock hazard. Exercise caution and wear appropriate Personal

Protective Equipment (PPE) safety gear, including high voltage safety

gloves and boots. Remove all metallic jewelry, including watches and

rings. Isolate the HV system as directed by the Ford Emergency Response

Guide for the vehicle. Failure to follow these instructions may result

in serious personal injury or death.

WARNING:

Electric vehicles damaged by a crash may have compromised

high voltage safety systems and present a potential high voltage

electrical shock hazard. Exercise caution and wear appropriate Personal

Protective Equipment (PPE) safety gear, including high voltage safety

gloves and boots. Remove all metallic jewelry, including watches and

rings. Isolate the HV system as directed by the Ford Emergency Response

Guide for the vehicle. Failure to follow these instructions may result

in serious personal injury or death.

NOTICE: Battery electric vehicle (BEV), hybrid electric vehicle (HEV) and plug-in hybrid electric vehicle (PHEV) contain a high-voltage battery. Before cutting or welding near the high-voltage battery it must be removed to avoid damage.

NOTICE: The high-voltage battery in a battery electric vehicle (BEV), hybrid electric vehicle (HEV) or plug-in hybrid electric vehicle (PHEV) can be affected and damaged by excessively high temperatures. The temperature in some body shop paint booths can exceed 60° C (140° F). Therefore, during refinishing operations, the paint booth temperature must set at or below 60° C (140° F) with a bake time of 45 minutes or less. Temperatures in excess of 60° C (140° F) or bake durations longer than 45 minutes will require the high-voltage battery be removed from the vehicle prior to placing in the paint booth.

NOTICE: If refinishing cure temperatures exceed 60° C (140° F), the charge port light ring on plug-in vehicles must be removed.

NOTICE: Do not carry out body side sectioning repairs in areas of door hinge, safety belt or striker anchoring points. Welding within 50 mm (1.96 in) of door hinge or striker locations may compromise structural integrity during a collision.

NOTICE: Sectioning within the door hinge portion of the A-pillar, B-pillar or dog leg portion of the quarter panel is not approved by Ford Motor Company.

NOTE: Factory welds may be substituted with resistance or metal inert gas (MIG) plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. Metal inert gas (MIG) plug welds must equal factory welds in both location and quantity.

NOTE: Do not begin removal of the vehicle body side until the replacement panel is available for reference.

NOTE: LH side shown, RH side similar.

NOTE: The following illustration is intended as a general guideline and is not all inclusive.

-

Suggested body side cut lines.

.jpg) |

-

Available body side service parts.

.jpg) |

-

Restore the vehicle dimensionally to pre-damage condition.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

As a general rule, sectioning cut points should be chosen to result in the smallest repair area possible.

-

Detrim the vehicle as necessary.

-

Only remove as much or the outer body side as necessary.

Use the General Equipment: Air Body Saw

Use the General Equipment: Spherical Cutter

Use the General Equipment: Spot Weld Drill Bit

-

NOTE: Where possible, create a backer plate from an unused portion of the old or replacement panel. This will create a stronger joint.

Cut replacement panel to fit the repair area and install.

Use the General Equipment: Locking Pliers

Use the General Equipment: Resistance Spotwelding Equipment

Use the General Equipment: MIG/MAG Welding Equipment

-

Rough finish all sectioning joints with a fibre-based

body filler, final finish sectioning joints and plug welds with a

conventional body filler.

-

Properly seal all joints to prevent moisture intrusion.

Water and moisture migrate toward horizontal joints and corrosion tends

to occur more rapidly in these areas.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Proceed with the refinishing process using a Ford approved paint system and manufacturers recommendations.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Reinstall vehicle trim as necessary.

Description and Operation - Vehicle Specific Body Construction

Description and Operation - Vehicle Specific Body Construction

For recommended metal repair guidelines and recommendations, refer to the following illustrations and: For additional information, refer to: Specifications (501-25 Body Repairs - General Information, Specifications)...

Other information:

Ford Escape 2020-2025 Service Manual: General Procedures - Cylinder Bore Taper

Check NOTE: Refer to the appropriate Section 303-01 for the specification. Measure the cylinder bore at the top, middle and bottom of piston ring travel in 2 directions as indicated. Verify the cylinder bore is within the wear limit. The difference indicates the cylinder bore taper. If the cylinder bore taper does not meet specification, bore the cylinder to the next oversize lim..

Ford Escape 2020-2025 Service Manual: Removal and Installation - Inner Quarter Panel

Special Tool(s) / General Equipment Resistance Spotwelding Equipment Scraper for Straight Edges Hot Air Gun 8 mm Drill Bit MIG/MAG Welding Equipment Spot Weld Drill Bit Locking Pliers Materials Name Specification Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM - Flexible Foam Repair3M™ 08463, LORD Fusor® 121 - Remo..

Categories

- Manuals Home

- 4th Generation Ford Escape Owners Manual

- 4th Generation Ford Escape Service Manual

- Locating the Pre-Collision Assist Sensors

- Switching the Rear Window Wiper On and Off. Reverse Wipe

- Drive Modes

- New on site

- Most important about car

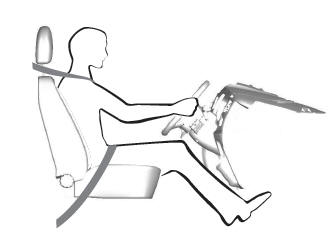

Sitting in the Correct Position

When you use them properly, the seat, head restraint, seatbelt and airbags will provide optimum protection in the event of a crash.